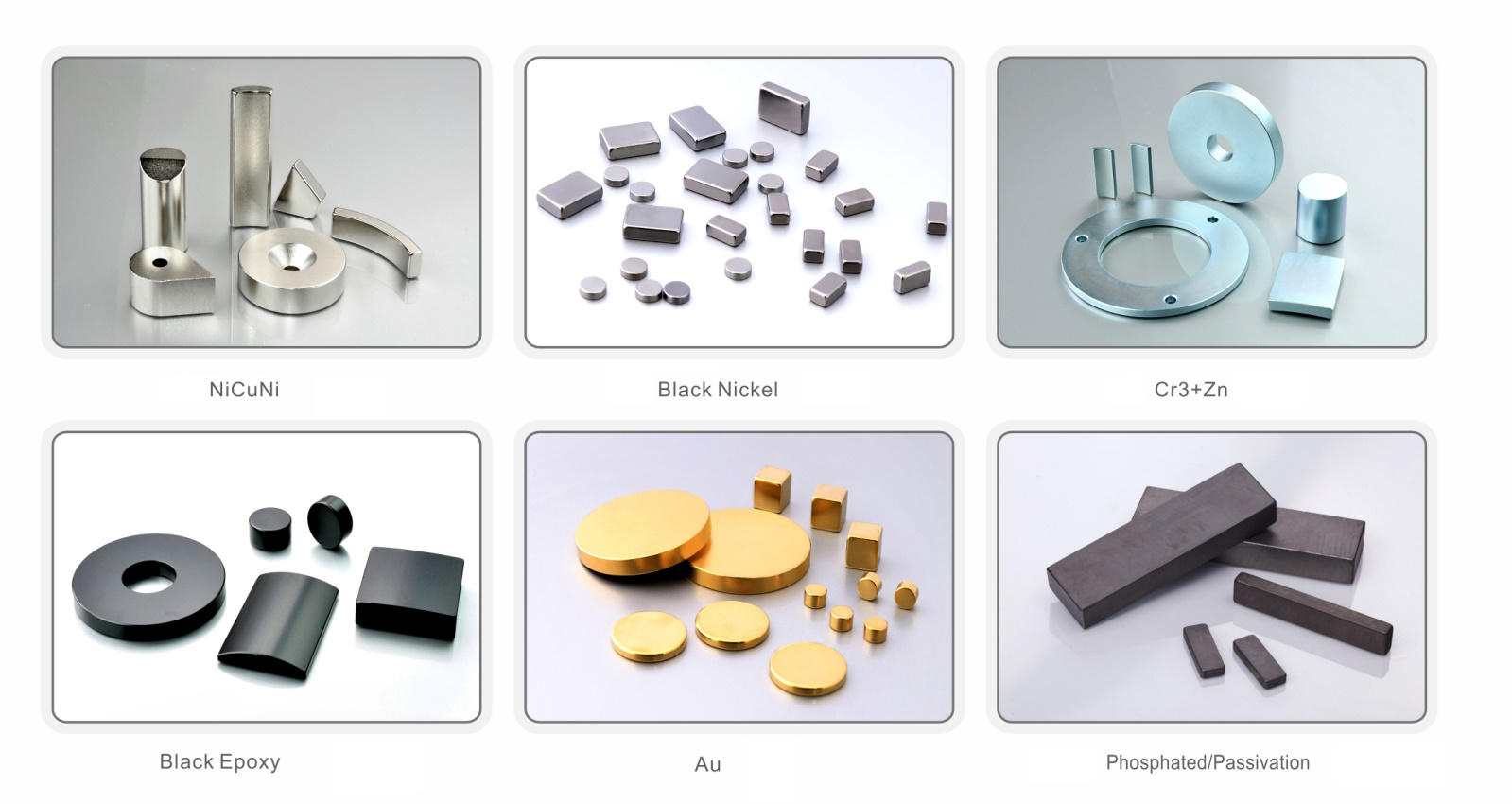

Material: Neodymium magnets Grade: N50, N52, 48M, 50M, 38H, 48H, 50H, 35SH, 38SH, 45SH, 48SH, 30UH, 35UH, 38UH, 42UH, 33EH, 38EH, 40EH, 33AH, 35AH, 38AH Product Dimensions: 0.01-200mm (Customized) Plating: Available in NiCuNi, Zn, Color Zn, Electroless Ni, Ni-Cu-Ni-Ag, Ni-Cu-Ni-Sn, Phosphate, Epoxy resin, Parylene, Everlube, Gold, Silver, Black nickle, Teflon Shape: Customized (Arc, block, bar, disc, rod, ring, sphere) Magnetization: Axially, Axially Multippole, Diametrically, Diametrically

Compact Size: Available in various small diameters, perfect for space-sensitive applications.

High Magnetic Field: Despite their small size, these magnets provide a powerful magnetic field.

Durable and Reliable: Constructed to withstand the test of time, ensuring long-lasting performance.

Versatile Applications: Suitable for use in electronics, automotive, aerospace, and more.

Customizable: Available in different grades and coatings to meet specific application requirements.

Electronics: Used in small motors, sensors, and hard drives.

Automotive: Ideal for compact motors and electronic components in vehicles.

Aerospace: Employed in various applications where weight and space are critical.

Consumer Products: Found in small appliances and personal electronics.

Grade: N35 to N52, with options for higher grades upon request.

Coating: Nickel, zinc, or epoxy coating for corrosion resistance.

Size Options: Diameters ranging from 0.2mm to 200mm, with customizable thickness.

Space-Efficient: Ideal for designs where space is a constraint.

High Performance: Delivers a strong magnetic pull for its size.

Longevity: Resistant to demagnetization and corrosion.

| Grade | Remanence | Coercivity | Intrinsic Coercivity | Max. Energy Product | Max. Working Temperature | ||||

| Br | Hcb | Hcj | (BH)max | ||||||

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ℃ | |

| N30 | 1.08-1.13 | 10.8-11.3 | ≥798 | ≥10.0 | ≥955 | ≥12 | 223-247 | 28-31 | 80 |

| N33 | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥955 | ≥12 | 247-271 | 31-34 | 80 |

| N35 | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 |

| N38 | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 |

| N40 | 1.25-1.28 | 12.5-12.8 | ≥907 | ≥11.4 | ≥955 | ≥12 | 302-326 | 38-41 | 80 |

| N42 | 1.28-1.32 | 12.8-13.2 | ≥915 | ≥11.5 | ≥955 | ≥12 | 318-342 | 40-43 | 80 |

| N45 | 1.32-1.38 | 13.2-13.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 342-366 | 43-46 | 80 |

| N48 | 1.38-1.42 | 13.8-14.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 366-390 | 46-49 | 80 |

| N50 | 1.40-1.45 | 14.0-14.5 | ≥796 | ≥10.0 | ≥876 | ≥11 | 382-406 | 48-51 | 80 |

| N52 | 1.43-1.48 | 14.3-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 398-422 | 50-53 | 80 |

| N55 | 1.46-1.52 | 14.6-15.2 | ≥796 | ≥10.0 | ≥876 | ≥11 | 414-430 | 52-54 | 80 |

| N35M | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 |

| N38M | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 |

| N40M | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 |

| N42M | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 |

| N45M | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 |

| N48M | 1.37-1.43 | 13.7-14.3 | ≥1027 | ≥12.9 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 |

| N50M | 1.40-1.45 | 14.0-14.5 | ≥1033 | ≥13.0 | ≥1114 | ≥14 | 382-406 | 48-51 | 100 |

| N52M | 1.43-1.48 | 14.3-14.8 | ≥1050 | ≥13.2 | ≥1114 | ≥14 | 398-422 | 50-53 | 100 |

| N54M | 1.45-1.50 | 14.5-15.0 | ≥1051 | ≥13.2 | ≥1114 | ≥14 | 414-438 | 52-55 | 100 |

| N35H | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120 |

| N38H | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120 |

| N40H | 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120 |

| N42H | 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120 |

| N45H | 1.32-1.36 | 13.2-13.6 | ≥963 | ≥12.1 | ≥1353 | ≥17 | 342-366 | 43-46 | 120 |

| N48H | 1.37-1.43 | 13.7-14.3 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 | 120 |

| N50H | 1.40-1.45 | 14.0-14.5 | ≥1011 | ≥12.7 | ≥1353 | ≥17 | 382-406 | 48-51 | 120 |

| N52H | 1.43-1.48 | 14.3-14.8 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 398-422 | 50-53 | 120 |

| N35SH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 |

| N38SH | 1.22-1.25 | 12.2-12.5 | ≥907 | ≥11.4 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 |

| N40SH | 1.25-1.28 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 |

| N42SH | 1.28-1.32 | 12.8-13.2 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 |

| N45SH | 1.32-1.38 | 13.2-13.8 | ≥1003 | ≥12.6 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 |

| N48SH | 1.37-1.43 | 13.7-14.3 | ≥1027 | ≥12.9 | ≥1592 | ≥20 | 366-390 | 46-49 | 150 |

| N50SH | 1.40-1.45 | 14.0-14.5 | ≥1003 | ≥12.6 | ≥1592 | ≥20 | 382-406 | 48-51 | 150 |

| N28UH | 1.04-1.08 | 10.4-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 | 180 |

| N30UH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 | 180 |

| N33UH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 |

| N35UH | 1.17-1.22 | 11.7-12.2 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 |

| N38UH | 1.22-1.25 | 12.2-12.5 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 |

| N40UH | 1.25-1.28 | 12.5-12.8 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 |

| N42UH | 1.28-1.32 | 12.8-13.2 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 318-342 | 40-43 | 180 |

| N45UH | 1.32-1.36 | 13.2-13.6 | ≥908 | ≥11.4 | ≥1990 | ≥25 | 342-366 | 43-46 | 180 |

| N48UH | 1.37-1.43 | 13.7-14.3 | ≥908 | ≥11.4 | ≥1990 | ≥25 | 366-390 | 46-49 | 180 |

| N28EH | 1.04-1.08 | 10.4-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 26-29 | 200 |

| N30EH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 |

| N33EH | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 |

| N35EH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 |

| N38EH | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 287-310 | 36-39 | 200 |

| N40EH | 1.25-1.28 | 12.5-12.8 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 302-326 | 38-41 | 200 |

| N42EH | 1.28-1.32 | 12.8-13.2 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 318-342 | 40-43 | 200 |

| N45EH | 1.32-1.36 | 13.2-13.6 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 342-366 | 43-46 | 200 |

| N28AH | 1.04-1.08 | 10.4-10.8 | ≥787 | ≥9.9 | ≥2786 | ≥35 | 207-231 | 26-29 | 230 |

| N30AH | 1.08-1.13 | 10.8-11.3 | ≥819 | ≥10.3 | ≥2786 | ≥35 | 223-247 | 28-31 | 230 |

| N33AH | 1.13-1.17 | 11.3-11.7 | ≥843 | ≥10.6 | ≥2786 | ≥35 | 247-271 | 31-34 | 230 |

| N35AH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥2786 | ≥35 | 263-287 | 33-36 | 230 |

| N38AH | 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥2786 | ≥35 | 287-310 | 36-39 | 230 |

| The above-mentioned data of magnetic properties and physical properties are given at room temperature. | |||||||||

| The max working temperature of magnet is changeable due to length-diameter ratio, coating thickness and other environment factors. | |||||||||

Over a decade of manufacturing and market experience, we understand the diverse technical requirements of different customers.

We are a strategic partner to several Fortune Global 500 companies, ensuring our product quality and after-sales service are guaranteed.

We fully accommodate customer requests for samples and small batch trial orders.

We offer a competitive pricing system and fast delivery times because we are a genuine large-scale manufacturer.

We provide professional advice and consulting services, especially when your project is in the design phase.

Your Premier Source for Magnetic Materials and C

Explore the critical differences between electro

Contact: Wayne Zhang

Phone: 86-150-5753-5223

Tel: 86-135-8809-8640

Email: info@vnmagnets.com

Add: No.358 Estern Fengqi Road, Shangcheng Hangzhou China

We chat