Housing Material: Stainless Steel 304 / 316L (Food Grade) Magnetic Strength: 8000 Gauss / 10000 Gauss / 12000 Gauss (Customizable) Max Operating Temp: Standard 80°C (Up to 350°C High-Temp model available) Pressure Rating: Standard 6-10 Bar (High pressure customizable) Connection Type: Flange, Clamp (Quick Release), or Threaded

Ensure the purity of your liquid products with VN Magnets' Sanitary Magnetic Liquid Trap. Designed for critical industrial applications, this pipeline separator effectively captures fine ferrous contaminants and tramp iron from liquid lines, slurries, and gases.

Our liquid traps are constructed from high-quality SS304 or SS316L stainless steel to meet strict food and pharmaceutical hygiene standards. Equipped with high-intensity rare earth magnets (up to 12,000 Gauss), they provide reliable protection for your downstream equipment (such as pumps and mixers) while ensuring your final product meets safety regulations.

Ideal for liquid chocolate, syrups, chemical slurries, and beverage processing. Available in various connection types and custom sizes to fit your existing pipeline seamlessly.

| Product Name | Sanitary Magnetic Liquid Trap / Pipeline Separator |

| Housing Material | SS304 / SS316L (Food & Pharmaceutical Grade) |

| Magnetic Strength | 8000Gs / 10000Gs / 12000Gs (High Intensity) |

| Working Temperature | Standard 80°C (High-Temp Model up to 350°C) |

| Surface Finish | Fine Polished / Sand Blasted (Ra ≤ 0.6μm) |

| Connection Type | Flange, Tri-clamp (Quick Release), or Threaded |

| Pressure Rating | Standard ≤ 10 Bar (High Pressure Customizable) |

Food & Beverage: Removing fine iron from chocolate, syrup, juice, jams, and dairy lines.

Chemical Processing: Protecting pumps and mixers in liquid chemical slurries.

Pharmaceuticals: Ensuring product purity in liquid medicine production (Sanitary Grade).

Water Treatment: Filtration of ferrous contaminants in cooling water systems.

Q: How do I choose the connection type?

A: For food and pharmacy industries, we recommend the Tri-clamp (Quick Release) connection for easy cleaning. For high-pressure industrial lines, Flange connections are preferred.

Q: How often should I clean the magnetic trap?

A: It depends on the contamination level of your material. We recommend checking the magnetic tubes once per shift initially. We also offer an "Easy-Clean" design with a scraping sleeve to speed up the process.

Q: Can you customize the size?

A: Yes, as a direct manufacturer, we can customize the inlet/outlet diameter and the number of magnetic tubes to fit your existing pipeline flow rate.

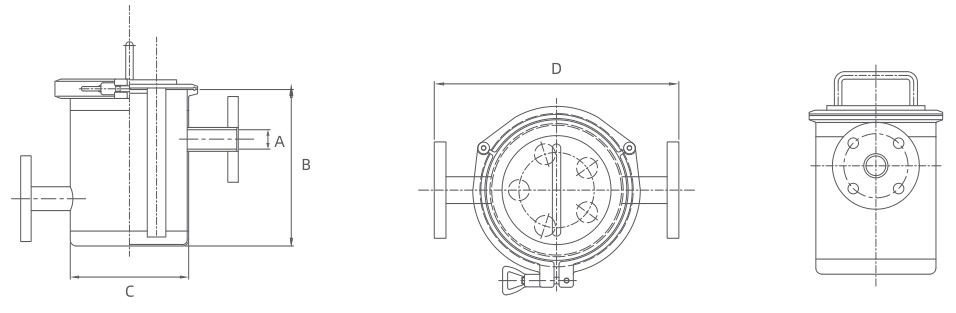

| MODEL | Dimension A (mm) | Dimension B (mm) | Dimension C (mm) | Dimension D (mm) | No. of Bars |

|---|---|---|---|---|---|

| VNMG25(DN25) | 26 | 180 | 159/219 | 250/300 | 5/6 |

| VNMG50(DN50) | 51 | 250 | 159/219 | 250/300 | 5/6 |

| VNMG65(DN65) | 70 | 260 | 219 | 300/360 | 5/6 |

| VNMG80(DN80) | 83 | 290 | 219 | 360 | 6/7 |

| VNMG100(DN100) | 102 | 290 | 219 | 360 | 6/7 |

Your Premier Source for Magnetic Materials and C

Explore the critical differences between electro

Contact: Wayne Zhang

Phone: 86-150-5753-5223

Tel: 86-135-8809-8640

Email: info@vnmagnets.com

Add: No.358 Estern Fengqi Road, Shangcheng Hangzhou China

We chat